I. Organising and repairing spare parts where necessary to ensure continuous production

I. Organising and repairing spare parts where necessary to ensure continuous production

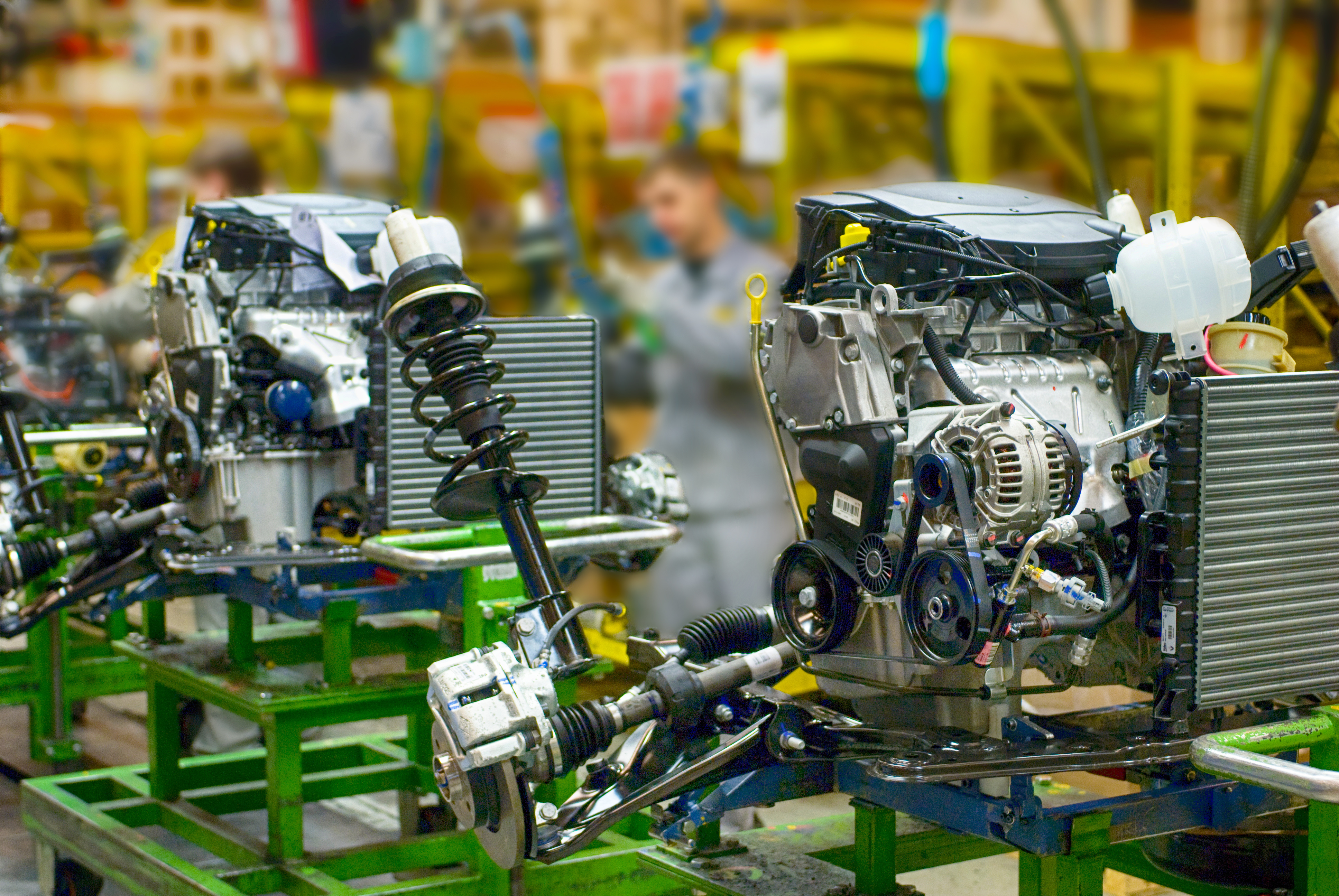

Stockpiling work: assembling kits, reparation sets

Conversion of electronic and electromechanical devices in workplaces that have

ESD protection workstations

Warehousing on own site, scheduled delivery

Preparation of preliminary sorting and delivery schedule

Transport of spare parts using own lorries

Preparation of statements, operational instructions, analyses

Immediate information on new fault types

Consulting, experience exchange, manufacture preparation-planning

II. Procurement and scheduled delivery of non-productive materials for industrial production.